|

SOFTWARE

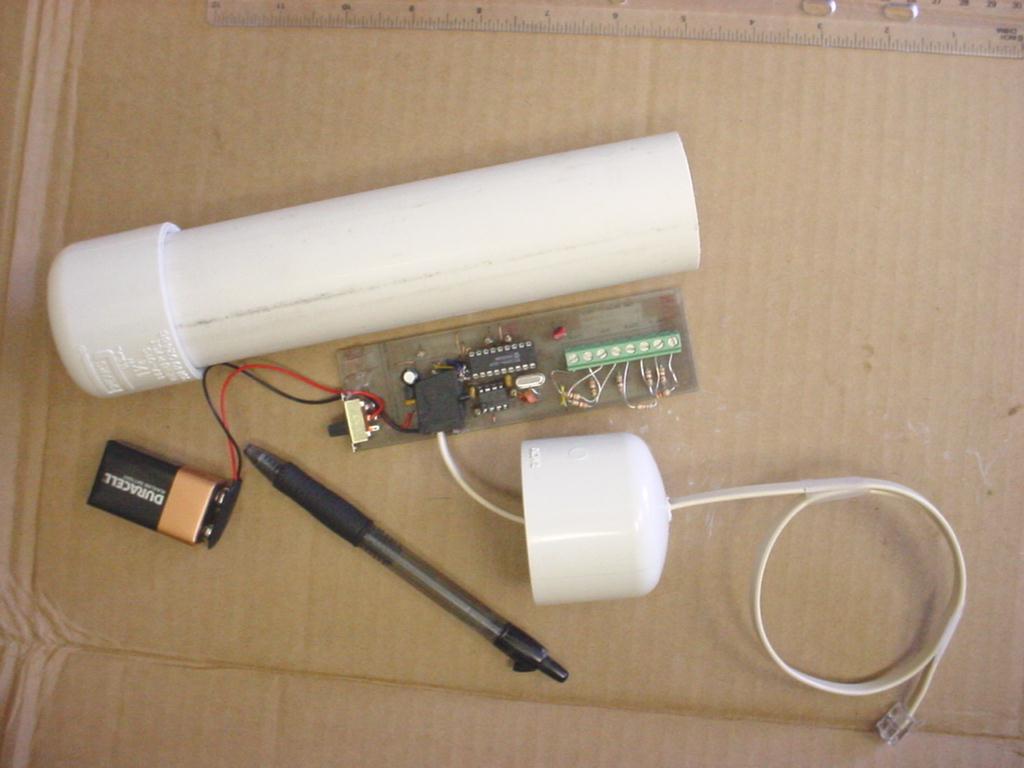

Two software programs are included with the

irrigation monitor. One, called the firmware is burned into the

microprocessor on the circuit board. The second program is on a

diskette to be loaded into a Microsoft Windows computer to control

the uploading of data.

The firmware controls the time interval between sensor reads.

Which, the user determines before placing the device in the field.

In addition, the firmware reads each sensor four times in a

sampling period and averages them. It then, reverses the direction

of current to the sensor to minimize the migration in ions in the

soil solution to the electrodes Finally, it saves the readings to

memory, and watches the time until the next read.

The PC program

allows the irrigation monitor data to be uploaded and formatted in

the form of a spreadsheet. The user can also set the time interval

between samples, and the accuracy of this time with this program.

User

Setup

Before placing the irrigation monitor in the field

the user must set the sampling interval. You can set this interval

from one minute to 256 hours. Of course, the time between uploads

determines the maximum number of samples that can be taken without

overfilling the memory . For example, you can see that at one

minute intervals the memory will fill in 136.5 hours, or 5 to 6

days. Whereas, an interval of 256 hours will allow just one read

in over 10 days..

For irrigation work a sampling time of 2 to 6 hours is

adequate. In this range the data logger can store data for 682 to

2048 days. As you can see there is plenty of extra storage space

for more detailed readings.

The user can also

adjust the accuracy of the data loggers clock. However, this

adjustment is temperature dependent and should be adjusted at the

site of operation.

SENSORS

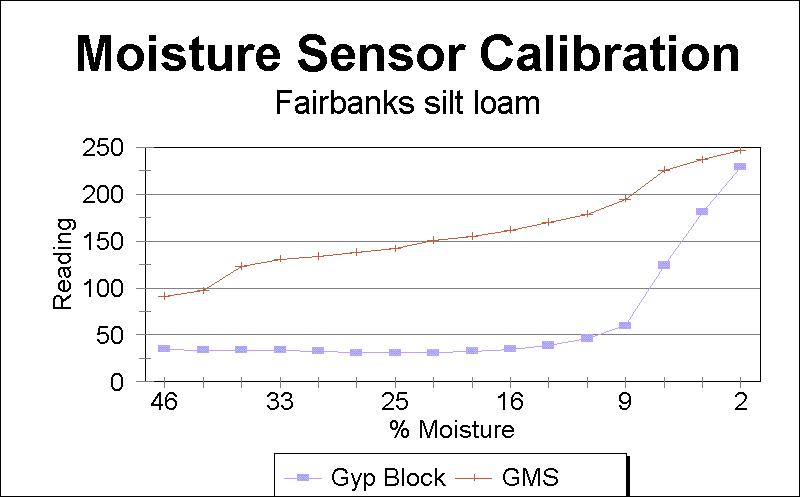

You can use two types of soil moisture sensors. Each type is an

electrical resistance device that measures soil water tension. The

two sensor types are the gypsum block, and the granular matrix

sensor (GMS), made by Watermark. There are both advantages and

disadvantages to each of these sensor types.

Back

to page top

|