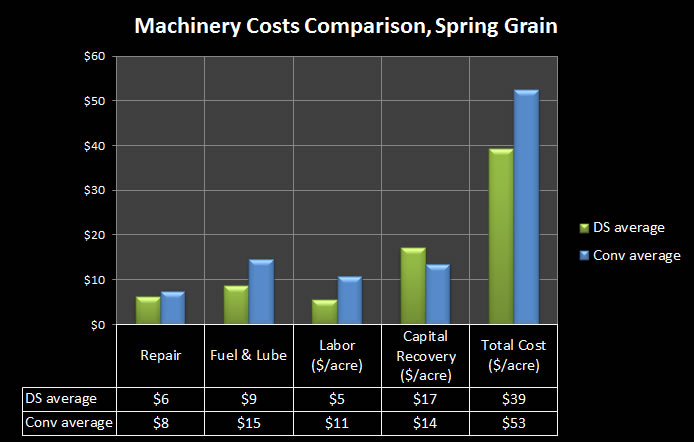

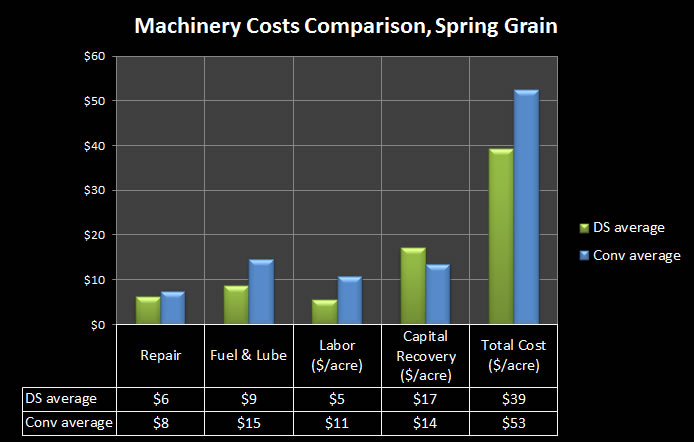

Machinery cost comparisons for surveyed direct seed and conventional tillage growers.

Results of this study show that cost savings rather than yield differences under direct seeding will drive the economics of direct seeding. Access to machinery remains the main barrier to further adoption. Variable production costs such as fuel, labor, and machinery repairs are reduced under direct seeding but fixed costs of machinery ownership are typically higher.

The majority of growers participating in this program did not see changes in yields under direct seeding. Two growers had higher yields for their direct seeded spring grains while one grower had lower yields; most of these differences can be explained by timing of the seeding. Direct seed mentors have higher than average crop yields for their areas. Further details, including crop budgets by rainfall zone, are available upon request.

Operating costs for machinery usage, including fuel, repair, and labor costs, were higher for conventional tillage (CT) growers in this survey (Figure 1). Repair costs are 28% higher for CT, at $7.33 per acre compared to $5.75 per acre for direct seed (DS) production. As expected, fuel and lube costs are lower for DS, averaging $9.22 per acre, compared to $14.66 per acre for CT, a savings of $5.45 per acre for DS. DS production averaged 3.89 gallons per acre, compared to 6.23 gallons per acre for CT (fuel use included harvesting and miscellaneous truck usage but excluded hauling to market outlets).

Another major difference between the two production methods is the difference in machine labor requirements. DS production averaged 0.27 hours per acre of machinery labor, compared to 0.52 hours per acre for CT. Valued at $20 per acre, machinery labor costs for DS were just 56% of the CT machinery labor expense.

One frequently stated barrier to DS production is the cost of DS machinery. DS drills are typically much more expensive than CT drills, with a good new DS drill costing nearly $200,000, compared to $80,000 for a top-of-the-line CT drill. Capital recovery costs in Table 1 refer to an annual cost for depreciation and interest in the machinery investment. These costs are about 40% higher for DS growers, averaging $19.41 per acre compared to $13.81 per acre (Figure 1).