|

RESEARCH

Research Interests

Nuclear Materials, Microstructure-Property

Correlations, High Temperature Mechanical

Behavior of Materials (Creep, Superplasticity and relevant

phenomena), Nanostructured Materials, Advanced Processing Techniques

(Additive Manufacturing, High Energy Ball Milling, Friction Stir Welding/Processing,

Spark Plasma Sintering)

Click

here to see an example

of the research work done by Dr. Charit's group and

collaborators.

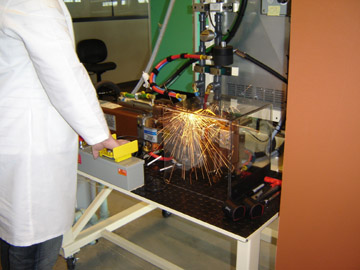

Research Equipment/Facilities

Our laboratory (Advanced

Materials Laboratory or AML) is located in McClure 422. The lab

is equipped with a simultaneous thermal analyzer, Lindberg high temperature furnaces, Buehler Isomet 1000 cutting machine, high energy ball milling equipment (SPEX Mill 8000M), SPEX-2380 bench press,

an inert atmosphere glove box, TEM sample preparation kit (Gatan

Disc Punch, Fischione Disc Grinder and Twin-Jet Polisher), and a

full metallography

facility including an Allied HighTech TwinPrep Grinder/Polisher.

The AML is equipped with three

mechanical test instruments: A Lever Arm (20:1) ATS 2335 Creep Tester that can easily perform tensile creep testing up to 700

degree C in air and potentially can go upto 1000 degree C; A universal tester (Instron 5982) primarily for

performing room temperature and high temperature tensile tests

(funded by a NE-UP

Infrastructure Grant) at different temperatures and strain

rates; and a Vickers microhardness tester (LECO LM100).

Sultan getting ready to start a tensile test /

working the hardness m/c Tri conditioning the creep tester

The Department of Chemical and Materials Engineering houses a

fully equipped machine-shop at the Buchanan Engineering Laboratory (BEL)

on-campus.

The Center for Electron Microscopy and Microanalysis, a

University of Idaho facility, has a LEO Supra 35VP field-emission-gun scanning

electron microscope (FEG-SEM), one AMRAY 1830 SEM, a JEOL transmission electron

microscope (TEM) and a Siemens D5000 X-ray diffraction equipment

are located in the McClure Hall and easily accessible.

Dr. Charit's group also utilizes

the state-of-the-art analytical instruments available at the

Center for Advanced Energy Studies (CAES) at Idaho Falls. These

include a High Resolution TEM, SEMs with Focused Ion Beam (FIB)

and Electron Backscatter Diffraction (EBSD) capabilities and Local

Electrode Atom Probe (LEAP). These instruments can provide

valuable information on the intrinsic structure of materials at

a very fine level. These instruments are used either as part of the funded NSUF users

facility projects or at a charge. A former PhD student (Somayeh)

has used

these instruments as part of her dissertation work. Furthermore,

the spark plasma sintering machine present at the

Advanced Materials Lab at CAES is accessible to Dr. Charit.

Somayeh

working with the HRTEM and LEAP instruments at CAES-MacS Lab Somayeh working on the

SPS machine at CAES

A pressure resistance welding (PRW)

machine was purchased from the Centerline Ltd. using an AFCI

grant. Currently, the machine is located at the

Instrumentation Shop at the CAES, Idaho Falls. Dr. Charit's

group has been successful in joining a variety of high

temperature metallic materials (MA956, MA957, HT-9, tungsten, molybdenum) using the PRW

technique.

Current Funded Projects

INL-LDRD: “Nanostructuring of Uranium-Based Metallic Fuels via Spark Plasma Sintering,” Total funding: $760,000, a subcontract co-PI, UI PI: S. Choudhury, 10/01/2020 - 09/30/2023. (subcontracting process underway).

“Mitigating Stress Corrosion Cracking in Austenitic Stainless-Steel Canister Welds Using Peening Techniques,” Nuclear Energy University Programs DOE Office of Nuclear Energy, PI: M. Misra (University of Nevada-Reno), co-PIs: I. Charit, K. Hollis (Los Alamos National Laboratory); Project Period: 10/1/2020 to 9/30/2023; Total Funding: $799,950 (Charit portion: $199,412).

“Optimizing Manufacturing of High Value Components Using Direct Metal Laser Melting Techniques under Reduced Atmospheric Conditions for Industrial Sectors,” Idaho Global Entrepreneurial Mission (IGEM), Idaho Department of Commerce, PI: I. Charit, Co-PIs: K.S. Raja, M. Maughan (University of Idaho), Brian Jaques (Boise State University), Michael McMurtrey (INL), Mark Jaster (Element7 / Consultant to Premier Technology), and Catherine Cantley (University of Idaho TechHelp); Project Period: 5/31/2019 to 6/30/2021; Total Funding: $274,167.

“Friction Stir Based Repair Welding of Dry Storage Canisters and Mitigation Strategies: Effect of Engineered Barrier Layer on Environmental Degradation,” Nuclear Energy University Programs DOE Office of Nuclear Energy, PI: I. Charit, Co-PIs: K.S. Raja (University of Idaho), Saumyadeep Jana (Pacific Northwest National Laboratory); Project Period: 10/1/2018 to 9/30/2021; Total Funding: $800,000.

Past Funded Projects

“A Science Based Approach for Selecting Dopants in FCCI-Resistant Metallic Fuel Systems,” Nuclear Energy University Programs (NEUP), DOE Office of Nuclear Energy; I. Charit (PI), S. Choudhury (Co-PI); R. Mariani and M. Benson, Idaho National Laboratory (Co-PIs); Project Period: Oct. 1, 2016 to Sep. 30, 2019 (extended to Sep. 30, 2020); Total Funding: $800,000.

“General Scientific Infrastructure Support for Innovative Nuclear Research at the University of Idaho,” Nuclear Energy University Programs Infrastructure Program, DOE Office of Nuclear Energy; PI: V. Utgikar, Co-PIs: R.N. Christensen, H. Zhao, G. Potirniche, R.S. Stephens, I. Charit and K.S. Raja; Project Period: 10/1/2017 to 9/30/2018; Total Funding: $247,471.

“Microscale Technique to Evaluate Grain Boundary Cohesion of Irradiated Alloys,” Idaho National Laboratory LDRD; PI: Chao Jiang (INL), Co-PIs: B. Jaques (Boise State University), R. Fertig (University of Wyoming), I. Charit (University of Idaho), W. Jiang (INL); Project Period: 5/1/2016 to 9/30/2018; Total Funding: $150,000.

“Characterization of Creep-Fatigue Crack Growth in Alloy 709 and Prediction of Service Lives in Nuclear Reactor Components,” US DOE Nuclear Energy University Programs (NEUP); PI: G.P. Potirniche, Co-PIs: R. Stephens, I. Charit, A. Tokuhiro (Purdue University), M. Glazoff (Idaho National Laboratory); Project Period: 10/1/2015 to 9/30/2018; Total Funding $799,927.

“Acquisition of a FEI Scios Electron Microscope,” Murdock Charitable Foundation, PI: S. Ay, Co-PIs: I. Charit, T. Williams, G. Potirniche, F, Barlow, D. Mcilroy, H. Saied, M. Gunter; Project Period: 1/1/2015 to 1/1/2018; Total Funding: $444,377.

“Boride-Based Electrode Materials with Enhanced Stability under Extreme Conditions for Magnetohydrodynamic (MHD) Direct Power Extraction,” University Coal Research Program, National Energy Technology Laboratory (NETL) through US DOE Office of Fossil Energy; PI: I. Charit, co-PI: K.S. Raja (University of Idaho); Project Period: 7/1/2014 to 6/30/2017; Total Funding $399,938.

“Integral Inherently Safe Light Water Reactor (I2S-LWR),” Integrated Research Program (IRP), Nuclear Energy University Programs; PI: B. Petrovic (Georgia Tech), co-PIs: F. Rahnema (Georgia Tech), A. Manera (University of Michigan), P. Ferroni (Westinghouse), A. Haghighat (Virginia Tech), W. Hines and B. Upadhyaya (University of Tennessee), I. Charit (University of Idaho), L. Muldrow (Morehouse College), A. Ougouag (Idaho National Laboratory), R. Cocherell (Southern Nuclear), G. Parks (University of Cambridge, UK), M. Ricotti (Italy); Project Period: 2/11/2013 to 9/30/2016; Total funding to Charit: $147,910.

“Studying the Microstructural Characteristics of Nuclear Fuels,” Battelle Energy Alliance, PI: I. Charit, Project Period - 8/18/2012 to 9/30/2013, Total Funding: $92,547.

“TAOI B - Computational Microstructural Optimization Design Tool for High Temperature Structural Materials,” University Coal Research Program, National Energy Technology Laboratory (NETL) through US DOE Office of Fossil Energy; PI: R.S. Mishra, University of North Texas; co-PI: I. Charit, Project Period: 9/1/2012 to 8/30/2014, Total Funding: $300,000.

“Course Modules on Management of Aging Power Plant Components and Systems for Enhancement of Nuclear Engineering Program,” US Nuclear Regulatory Commission (NRC) – Curriculum Development Program; PI: K.S. Raja, co-PIs: I. Charit, B. Pesic; Project Period: 4/1/2012 to 8/31/2013; Total Funding: $200,004.

“Undergraduate support by the University of Idaho for Microstructural Characterization of Spark Plasma Sintered Tungsten,” Idaho National Laboratory, PI: I. Charit, Project Period: 10/17/2011 to 06/15/2012, Total Funding: $6,123.

“Request to enhance the Experimental and Computational Capabilities to Support Nuclear Energy Research and Development,” Nuclear Energy University Programs (NE-UP) Infrastructure Grant, Project Period: 8/31/2010 to 8/30/2011; PI: A. Tokuhiro, co-PIs: G. Potirniche, C. Wai and I. Charit; Total Funding: $250,000.

“Fabrication of Advanced ODS Alloys Using Field Assisted Sintering,” Idaho National Laboratory LDRD Program; PI: J. Cole (Idaho National Laboratory), co-PIs: I. Charit and D.P. Butt (Boise State University), Project Period: 3/18/2010 to 9/30/2012, Total Funding to Charit: $234,122.

“Fabrication of Tungsten-Rhenium Cladding Materials via Spark Plasma Sintering for Ultra-High Temperature Reactor Applications,” Department of Energy through FY2009 Nuclear Energy University Program (NE-UP); PI/Project Director: I. Charit, co-PIs: Darryl P. Butt (Boise State University) and Mark Carroll (Idaho National Laboratory); 10/1/2009 to 9/30/2012, Total Funding: $682,258.

“Prediction and Monitoring Systems of Creep-Fracture Behavior of 9Cr-1Mo Steels for Reactor Pressure Vessels,” Department of Energy through FY2009 NE-UP Program, PI: Gabriel Potirniche, co-PIs: I. Charit, Karl Rink, Fred Barlow, Project Period - 10/1/2009 to 8/31/2013, Total Funding to UI: $503,188.

“Mechanical Properties of Nuclear Fuels,” Battelle Energy Alliance, PI: I. Charit, Program Manager: Rory Kennedy (Idaho National Laboratory), Project Period - 8/25/2008 to 8/17/2012, Total Funding to Charit: $319,101.

“Request for Graphite and Related Material Characterization Instrumentation in Support of NGNP and Advanced Reactor System,” NE-UP Infrastructure Program, 7/15/2009 to 7/14/2010, PI: A. Tokuhiro, co-PIs: V. Utgikar, I. Charit, S. Phongikaroon, Total Funding: $177,000 (Charit portion: $44,250).

“A Comparative Study of Welded ODS Cladding Materials for AFCI/GNEP Applications,” US DOE Office of Nuclear Energy (Advanced Fuel Cycle Initiative); PI: I. Charit, co-PIs: D.P. Butt (Boise State University), R.S. Mishra (University of Missouri-Rolla), K. Linga Murty (North Carolina State University), J. Cole, M. Meyer, L. Zirker (Idaho National Laboratory) and M. Woltz (Centerline Limited); Project period - 10/1/2008 to 9/30/2010; Total Funding: $458,762.

“Fuel Fabrication Using Friction Bonding Process to Support the RERTR Program,” Idaho National Laboratory, PI: I. Charit, Technical Monitors: D. Keiser, Jr. and Douglas Burkes (Idaho National Laboratory), Project Period: 5/15/2008 to 5/31/2009, Total Funding to Charit: $11,704.

“Acquisition of a Simultaneous Thermal Analyzer for GNEP (Global Nuclear Energy Partnership) Research and Training at University of Idaho,” US DOE Office of Nuclear Energy (GNEP University Readiness Program), PI: I. Charit, Project Period: 8/30/2007-2/29/2008, Total Funding: $99,945

“Studying Radiation Effects on Alloys,” Idaho National Laboratory, PI: I. Charit, Project Period: 8/15/2007 to 8/31/2008, Technical monitor: Douglas Burkes (INL), Total Funding: $70,799. |